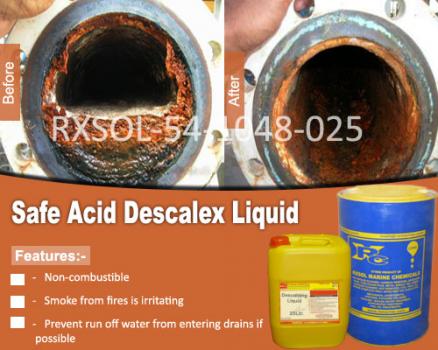

Safe Acid for flushing HVAC

Time to time cleaning and removal of contamination from refrigeration and air conditioning systems is a wise decision to stop failures and increasing the efficiency of HVAC SYSTEM . The most common such failure is a compressor burnout. During such an event, the refrigeration system becomes contaminated with large quantities of disintegrating particulate, sludge, acids, carbon residues, and possibly moisture. All of these contaminants must be removed before the system is returned to duty.

When flushing a system:

Do not inject the RXSOL SAFE ACID Product Code RXSOL-54-1048-025 into the compressor itself. In fact, the compressor should be removed or bypassed. Only the supporting refrigeration system should be flushed.

Large systems should be disassembled and flushed each part and accessory section by section.

Required quantities of RXSOL SAFE ACID is completely depends up on degree and deposition of contamination

After Flushing If these components appear to be contaminated, Repeat the process.

EQUIPMENT REQUIRED

The following equipment is required for each flushing operation:

New canisters of flushing a typically soiled system.

An injection tool and standard refrigerant charging hose to inject the solution into the system. Ideally the solvent in the container must be visible, so it can be inspected during the flushing process. This enables a technician to determine when the solvent begins to run clean, indicating that the system has been thoroughly purged.

A tank of clean compressed nitrogen, regulated to 120-150 psig. This tank should be equipped with a dispensing hose and will be used to purge the solvent from the system.

A vacuum pump with the appropriate hoses and clamps.

Clean wipes or swabs to remove any residual oils or liquids that may drip or be spilled while purging the system.

Safety equipment; never flush a system without eye protection and rubber gloves. Convoluted piping in certain systems can cause momentary spikes in the solvent flow during the flushing process, resulting in erratic purges, which can splash into eyes and onto skin.

SPECIFIC INSTRUCTIONS

1. Confirm you have all the required components for the service as well as for the flushing operation prior to beginning.

2. If the system is still operational, remove the existing refrigerant and lubricant and disassemble sections so individual portions can be cleaned section by section.

3. Disconnect fully all of the electrical connection and Disconnect the old compressor and remove it from the system. Remove filter-drier cores. (If it is easier or more cost-effective, install a bypass loop around the filter-drier accumulators, etc.) On heat pumps, remove check valves and four-way reversing valves. Again, configure and install bypass loops.

4. Connect a waste container to a discharge port to capture the contaminated flushing Liquid, need to be captured for proper disposal.

5. Connect your charging hose onto the system to be flushed. Make sure openings upstream — except the discharge port — are closed. Connect the injection tool to the canister. It is a good idea to restrict the drain or discharge point, so that the flushing solvent is prohibited from passing through so quickly. This will improve the cleaning process.

6. When ready to inject the flush, connect the canister to the charging hose. Open valve on tool; the flush will start entering the system.

7. Discharging the flush should take approximately 10 minutes, depending upon temperature. Before the tank is empty, some small quantity of solution should begin to flow into the discharge container. Also, the canister has been designed to empty itself completely only when it is standing in an upright position. Do not attempt to flush the system with a canister inverted or on its side.

8. Using the compressed nitrogen tank, connect the tank to the system and blast it into the system behind the flush solution. The nitrogen will push the solution through the entire system, agitating it and “scrubbing” the inside of the system. Eventually, all of the solvent will flow into the receiving container on the other side of the system. In this step, it is recommended that the nitrogen be used at a low pressure at first, with the pressure being allowed to increase gradually.

9. Observe the solution being captured by the receiving container. If it is running clean and clear, the system has been successfully flushed. If the solution is murky or still contains particulate, flush again.

10. After Cleaning neutralize the entire system by using RXSOL ALKALINE CLEANER SAFETY Liquid RXSOL-20-2004-025, This will increase the shelf lif of all METAL parts and equipemt.

11. Make your repairs. Remove any bypass loops you installed. Tie in the expansion devices. Replace the filter-drier cores. Secure the system.

12. Evacuate the system to a low micron pressure range with the vacuum pump and leak-check the system. This will evacuate any residual liquid solution from the system. As the internal pressure drops, the solvent will boil into vapor and be removed from the system. Time for pulling the vacuum should be approximately 15 minutes for a 5-ton system.

13. As a final step, recharge the system with refrigerant and lubricants as recommended by the compressor or equipment manufacturer and the system instructions. Reconnect electrical and electronic connections. Test the operation of the system. Wipe down the system, leaving the work area neat and clean.

14. Refer MSDS of the product before USE.